On November 16th at 1:00 PM ET ITI will present a 30 minutes webinar that coalesces years of our project experience and technical expertise into five useful insights for addressing what has become a major gap in Model Based Enterprise (MBE) implementations.

The adoption of 3D Model Based Definition (MBD), PLM, and digital manufacturing technologies requires an unprecedented level of 3D product data precision and accuracy. Therefore, an increasing focus for engineering and manufacturing leaders is minimizing the re-creation of 3D product data.

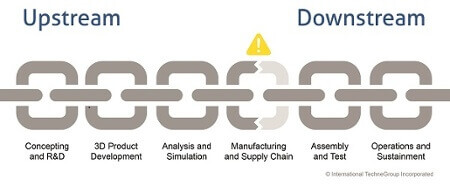

When downstream data consumers are reluctant to trust or are unable to use the 3D data, some may choose to re-create the released model, resulting in wasted labor and production issues that stem from unauthorized or unintended design changes.

Successful implementations of MBE identify these gaps earlier in the manufacturing process, implement real-time methods for identifying, documenting, and communication changes to 3D production data, and reduce such changes.

This webinar offers five insights for engineering and manufacturing groups implementing MBE.

- Examining processes and user actions that may prevent downstream reuse of 3D models

- Measuring and documenting manufacturing labor costs due to changes to MBD models

- Evaluating partner and supply chain workflows and processes for potential MBD data quality issues

- Implementing automated methods for identifying upstream and downstream MBD model changes

- Closing the feedback loop by using an instant, automated approach for documenting and communicating change

Click here to discover Model-Based solutions you can adopt in your organization.