La visualisation des données 3D représente aujourd'hui un enjeu stratégique dans le développement produit. Alors que les modèles CAO gagnent en complexité, les solutions de visualisation intégrées aux systèmes PLM comme CIM Database doivent évoluer pour maintenir des performances optimales. La solution standard 3D Connect proposée par Contact Software est-elle suffisante face aux assemblages complexes? Comment garantir l'accessibilité des données CAO à tous les intervenants sans compromettre la performance?

Ce guide approfondi analyse les défis spécifiques d'intégration de visualisation CAO dans l'environnement Contact Software et présente comment la solution 3DViewStation WebViewer répond aux besoins des utilisateurs exigeants en combinant performance, accessibilité et sécurité des données.

Table des matières

- Défis actuels de la visualisation CAO dans les environnements PLM

- Limites des solutions de visualisation standard pour CIM Database

- 3DViewStation WebViewer : solution performante pour Contact Software

- Bénéfices techniques et opérationnels de l'intégration avancée

- Architecture d'intégration et flux de données bidirectionnel

- Cas d'utilisation sectoriels et retours d'expérience

- Stratégie d'implémentation et optimisation des performances

- Perspectives d'évolution et conclusion

Défis actuels de la visualisation CAO dans les environnements PLM

La visualisation des données CAO constitue un élément fondamental du processus de développement produit moderne. Elle permet aux différents membres de l'équipe de travailler sur les mêmes modèles 3D, de les modifier, de les évaluer et de les partager sans nécessiter de licences CAO coûteuses.

Dans le contexte des systèmes PLM comme CIM Database de Contact Software, plusieurs défis se présentent concernant l'intégration efficace de la visualisation CAO :

- La complexité croissante des assemblages CAO, atteignant parfois plusieurs centaines de milliers de composants

- Les performances de chargement qui se dégradent proportionnellement à cette complexité

- L'accessibilité nécessaire pour différents profils d'utilisateurs techniques et non-techniques

- Le besoin d'accès en ligne et hors ligne aux données de conception

- La protection du savoir-faire et de la propriété intellectuelle

Ces défis sont particulièrement aigus dans les secteurs comme l'automobile, l'ingénierie industrielle et l'électronique, où la complexité des produits continue d'augmenter, rendant insuffisantes les solutions de visualisation standard.

Limites des solutions de visualisation standard pour CIM Database

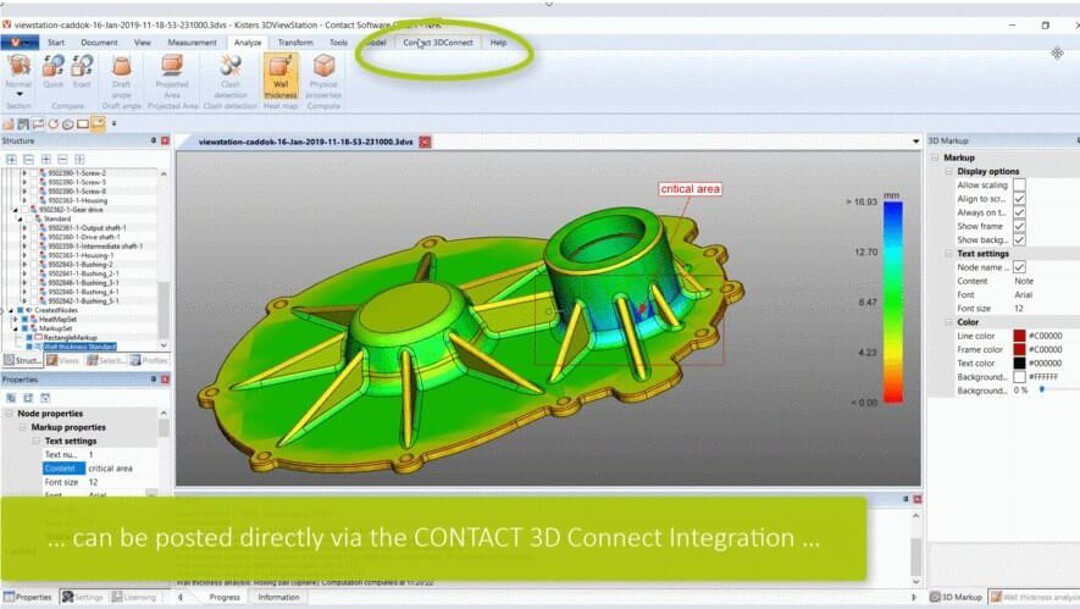

Contact Software propose nativement une solution de visualisation appelée 3D Connect, intégrée à sa plateforme CIM Database PLM. Cette solution répond aux besoins basiques de visualisation mais présente des limitations significatives lorsque les assemblages atteignent une certaine complexité :

| Aspect | Limitations de 3D Connect (solution standard) |

|---|---|

| Performance | Ralentissements significatifs avec les assemblages complexes |

| Formats supportés | Support limité des formats CAO natifs |

| Fonctionnalités analytiques | Capacités restreintes pour l'analyse technique approfondie |

| Accessibilité | Dépendance aux installations locales |

Ces limitations deviennent problématiques dans plusieurs contextes d'utilisation :

- Lorsque les équipes techniques doivent analyser des ensembles complexes

- Quand les collaborateurs distants ou mobiles ont besoin d'accéder aux données sans installation locale

- Pour les équipes pluridisciplinaires qui doivent partager et collaborer sur les modèles 3D

- Dans les situations où la performance devient critique pour maintenir l'efficacité des processus

C'est précisément dans ces contextes qu'une solution de visualisation avancée comme 3DViewStation WebViewer devient pertinente pour compléter l'environnement Contact Software.

3DViewStation WebViewer : solution performante pour Contact Software

La version WebViewer de 3DViewStation représente une évolution significative dans l'approche de la visualisation CAO intégrée aux systèmes PLM. Cette solution se distingue par plusieurs caractéristiques clés qui en font un complément idéal à l'environnement Contact Software :

Fonctionnalités principales du WebViewer

- Performances exceptionnelles même avec une bande passante limitée

- Aucune géométrie stockée sur l'appareil client, renforçant la sécurité

- Support étendu des formats 3D et 2D

- Plus de 180 fonctionnalités interactives aussi riches que la version Desktop

- Protection efficace du savoir-faire et de la propriété intellectuelle

- Zéro installation, zéro administration côté client

Le 3DViewStation WebViewer répond particulièrement bien aux besoins des utilisateurs occasionnels, des équipes mobiles et des partenaires externes qui nécessitent uniquement un accès aux données d'inventaire sans installation complexe.

Comparaison avec la solution standard

| Fonctionnalité | 3D Connect (standard) | 3DViewStation WebViewer |

|---|---|---|

| Performance avec assemblages complexes | Limitée | Excellente (chargement ultrarapide) |

| Installation requise | Oui | Non (basé sur navigateur) |

| Fonctions analytiques | Basiques | Avancées (>180 fonctionnalités) |

| Support formats natifs | Limité | Étendu |

| Sécurité des données | Standard | Renforcée (sans géométrie locale) |

Cette approche basée sur navigateur présente l'avantage considérable de rendre les données CAO accessibles partout, tout en maintenant un niveau de performance élevé grâce à une gestion intelligente des données et du format 3DVS ultraléger.

Bénéfices techniques et opérationnels de l'intégration avancée

L'intégration de 3DViewStation WebViewer dans l'environnement Contact Software génère des bénéfices tangibles à plusieurs niveaux :

Bénéfices pour les utilisateurs techniques

- Visualisation en ligne et hors ligne selon les besoins

- Chargement ultrarapide des assemblages complexes au format 3DVS

- Nombreuses fonctionnalités interactives sans formation approfondie

- Fonctionnalités d'analyse avancées (épaisseur de paroi, comparaison de versions)

- Utilisation de l'Activity Stream pour partager des snapshots directement

Bénéfices pour les décideurs et l'organisation

- Solution optimale pour les données CAO natives et complexes

- Alternative performante à la visualisation standard

- Efficacité de travail considérablement améliorée

- Satisfaction utilisateur accrue

- Contrôle des coûts via des modèles de licences concurrentes

- Protection optimisée du capital intellectuel

Cette intégration répond particulièrement aux besoins des utilisateurs professionnels ayant des exigences spécifiques, comme l'analyse technique poussée, tout en offrant une flexibilité d'utilisation qui s'adapte aux conditions de travail modernes.

Architecture d'intégration et flux de données bidirectionnel

L'intégration de 3DViewStation WebViewer avec CIM Database repose sur une architecture technique robuste qui permet un échange bidirectionnel des données et une expérience utilisateur fluide.

Principes d'intégration technique

Le 3DViewStation WebViewer s'approvisionne en données directement depuis Contact Elements et la base de données CIM. Cette intégration permet :

- Un accès direct aux modèles CAO, pièces, variantes et structures produit

- La navigation intuitive via le Cockpit 3D, outil central de l'interface

- Le renvoi des modifications et informations complémentaires vers le système de gestion des données

- Le chargement des structures produit virtuelles pour analyse approfondie

- Le transfert des résultats vers les processus de gestion documentaire ou de communication

- Le partage direct d'instantanés via le composant Activity Stream de Contact

Cette architecture garantit que les données circulent de façon cohérente entre le système PLM et l'outil de visualisation, sans duplication ni perte d'information.

Optimisation des performances

Un aspect crucial de cette intégration concerne l'optimisation des performances, particulièrement pour les assemblages complexes. La solution préconise :

- La conversion des données CAO au format 3DVS ultraléger lors de l'enregistrement dans CIM Database

- L'utilisation de l'outil batch KAS connecté au serveur de conversion Contact

- Le chargement quasi instantané des assemblages complexes (100 000+ composants en 1 seconde)

Cette approche intelligente de gestion des données répond directement au problème de performance croissante des modèles CAO modernes, sans nécessiter d'investissements matériels disproportionnés.

Cas d'utilisation sectoriels et retours d'expérience

Plusieurs secteurs industriels bénéficient déjà de l'intégration de 3DViewStation WebViewer avec Contact Software, chacun avec des cas d'usage spécifiques :

Industrie automobile

Dans le secteur automobile, où les assemblages peuvent atteindre des centaines de milliers de composants, l'intégration permet :

- La revue collaborative des conceptions entre équipes internationales

- L'analyse rapide des interférences et problèmes d'assemblage

- Le partage sécurisé des modèles avec les fournisseurs

- L'utilisation de maquettes numériques pour la validation précoce

Ingénierie industrielle

Pour les entreprises d'ingénierie industrielle, les avantages incluent :

- La visualisation des structures complexes d'usines et d'équipements

- L'intégration des données PLM/ERP dans la visualisation

- L'accès mobile aux données d'installation pour les équipes terrain

- La documentation technique interactive avec modèles 3D

Électronique

Dans le secteur électronique, l'intégration facilite :

- L'analyse des circuits complexes et PCB

- La visualisation des interactions mécaniques-électroniques

- La communication entre équipes hardware et software

- La validation des concepts d'intégration

Ces exemples concrets démontrent la polyvalence de la solution et sa capacité à s'adapter aux besoins spécifiques de chaque secteur industriel tout en maintenant l'intégrité des données dans l'écosystème Contact Software.

Stratégie d'implémentation et optimisation des performances

La mise en œuvre réussie de l'intégration 3DViewStation WebViewer avec Contact Software nécessite une approche méthodique qui maximise les bénéfices tout en minimisant les perturbations.

Étapes clés d'implémentation

- Évaluation des besoins : Identification des processus métier nécessitant une visualisation avancée

- Configuration de l'infrastructure : Mise en place du serveur 3DViewStation et intégration avec l'infrastructure Contact existante

- Configuration du serveur de conversion : Paramétrage de la conversion automatique vers le format 3DVS

- Intégration des interfaces utilisateur : Intégration transparente dans l'expérience utilisateur CIM Database

- Définition des droits d'accès : Configuration des autorisations alignées avec la structure Contact

Optimisation des performances

Pour maximiser les performances du système intégré, plusieurs stratégies sont recommandées :

- Conversion systématique des données CAO au format 3DVS lors de l'enregistrement initial ou après modification

- Configuration optimale du cache serveur pour les données fréquemment consultées

- Mise en place de politiques de nettoyage pour les données temporaires

- Optimisation des paramètres réseau pour la distribution efficace des données

Ces stratégies permettent d'atteindre des temps de chargement exceptionnels, comme des assemblages de 100 000 composants en 1 seconde, ou des structures plus complexes (navire de 10 millions de composants) en 15 secondes - des performances inégalées dans l'industrie.

Perspectives d'évolution et conclusion

L'intégration de solutions de visualisation avancées comme 3DViewStation WebViewer dans l'écosystème Contact Software représente une tendance de fond dans l'évolution des systèmes PLM modernes.

Tendances futures

Plusieurs évolutions sont anticipées dans ce domaine :

- Intégration croissante de technologies de réalité augmentée et virtuelle

- Développement d'analyses prédictives basées sur les modèles 3D

- Collaboration en temps réel multi-utilisateurs sur les modèles

- Optimisation continue des performances pour des assemblages toujours plus complexes

- Extension vers des cas d'usage métier au-delà de l'ingénierie (marketing, vente, support)

Conclusion

L'intégration de 3DViewStation WebViewer avec Contact Software (CIM Database PLM) répond à un besoin fondamental des organisations industrielles modernes : rendre les données CAO accessibles, performantes et sécurisées pour l'ensemble des acteurs du cycle de vie produit.

Cette solution permet de transcender les limitations des outils de visualisation standard en offrant :

- Des performances exceptionnelles même avec les assemblages les plus complexes

- Une accessibilité universelle via une approche basée sur navigateur

- Une richesse fonctionnelle comparable aux outils spécialisés

- Une protection optimale des données sensibles

- Une intégration bidirectionnelle fluide avec l'écosystème PLM existant

Pour les entreprises utilisant Contact Software qui cherchent à optimiser leurs processus d'ingénierie collaborative, l'intégration de 3DViewStation WebViewer représente une évolution stratégique qui combine performance technique, accessibilité utilisateur et sécurité des données - trois piliers essentiels de la transformation numérique industrielle.