Table of Contents

- Introduction to ZW3D and Interoperability

- History and Evolution of ZW3D

- The Overdrive Geometric Engine

- Formats and Standards Supported by ZW3D

- Interoperability with Other CAD Systems

- SimLab: Immersive Experience Solution for ZW3D

- Best Practices for Exchanging ZW3D Models

- Conclusion

Introduction to ZW3D and Interoperability

Computer-aided design data interoperability represents a major challenge for industrial companies working with multiple CAD systems. ZW3D positions itself as a high-performance solution to these technical data exchange issues, offering a complete response to CAD interoperability needs.

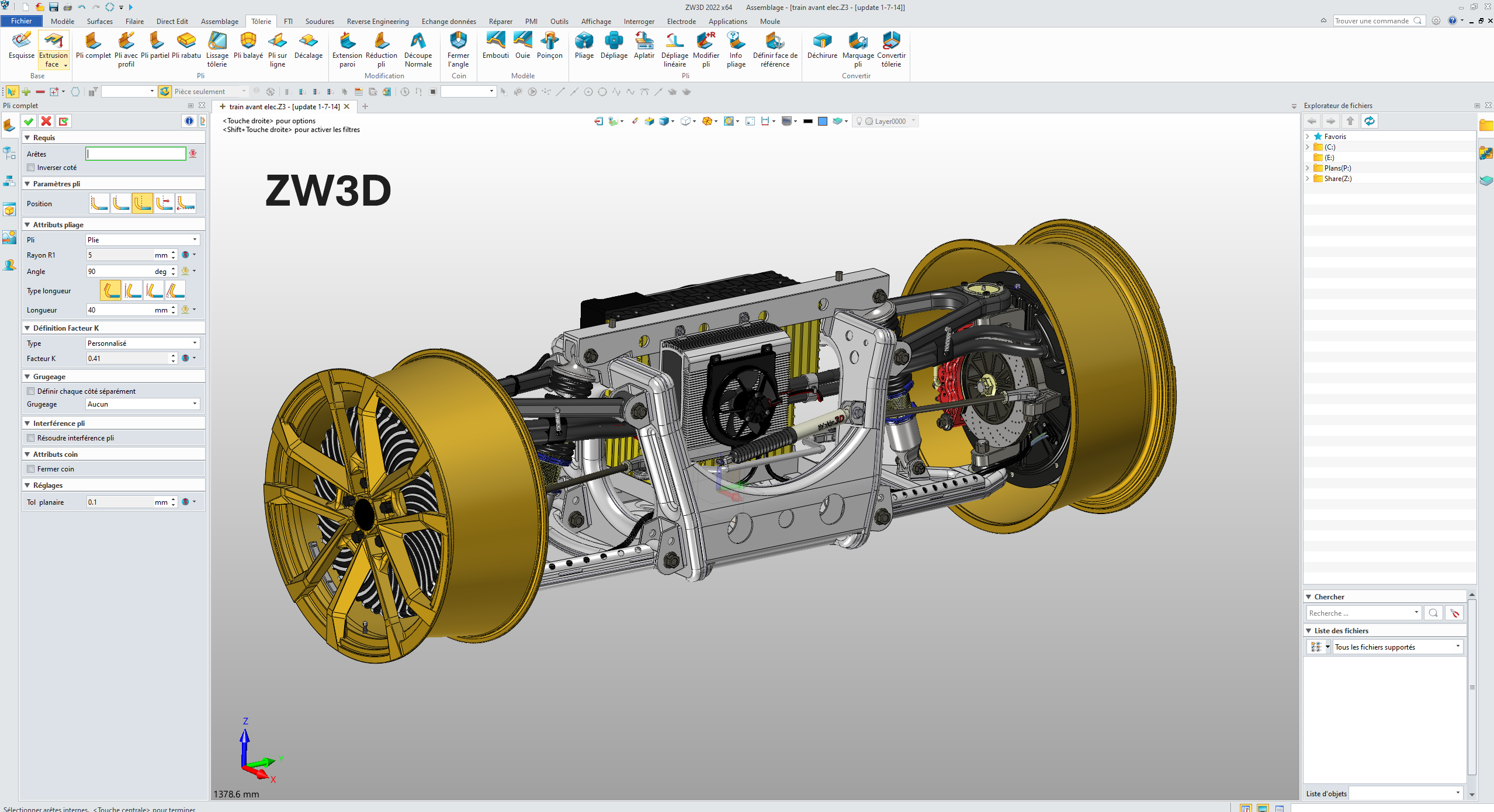

ZW3D is an advanced 3D CAD/CAM software developed by ZWSOFT, designed to offer an all-in-one solution for product design, manufacturing, and simulation. What particularly distinguishes ZW3D is its exceptional native interoperability capability with most CAD systems on the market.

The main advantages in terms of interoperability are:

- Direct opening of native files from many competing CAD systems

- Wide range of import and export formats

- Data translation without loss of geometric quality

- No need for third-party converters or add-ons in most cases

- Easy sharing and exchange with partners and suppliers

History and Evolution of ZW3D

Innovative Origins

Appearing in the CAD landscape in 1986 under the original name ModelMATE, ZW3D represented one of the very first commercial solid modelers operating on PC. Developed by Mark Vorwaller, this software already foreshadowed the future importance of technical data interoperability.

The year 1999 marks a decisive turning point with the introduction of Solid-Surface hybrid modeling technology, making ZW3D the first hybrid modeler in the industry. This major innovation removed the traditional boundaries between solid and surface modeling, allowing solid functionalities to be applied directly to surfaces.

Recognition and Continuous Development

Following a strategic alliance with SNK (Japanese machine tool company), ZW3D transformed into one of the first complete integrated design-manufacturing solutions. This evolution earned it the prestigious "Gold Winner & Product of the Year" award from NASA Tech Brief in 2002.

In 2010, ZWSOFT acquired the technologies and R&D team of VX Corporation in the United States, significantly enriching its multi-CAD interoperability and data exchange capabilities. Since then, ZW3D's continuous development has focused on improving data exchange performance with the main players in the CAD market.

The Overdrive Geometric Engine

A Powerful Proprietary Geometric Kernel

The core of ZW3D's CAD interoperability lies in its Overdrive geometric engine, a 3D modeling technology with completely independent intellectual property. Developed over more than 10 years, this kernel ensures the consistency of 3D models in their geometric shapes and spatial relationships thanks to sophisticated algorithms.

Overdrive offers a unique combination of features focused on interoperability:

- Smooth import and export of models from/to other systems

- Automated detection and repair of geometric defects

- Hybrid solid-surface modeling in a unified environment

- Coexistence of parametric and direct modeling

- Direct boolean operations between solids and surfaces

Proven Industrial Applications

The Overdrive engine has proven its effectiveness in various industrial sectors such as automotive, mechanical engineering, and electronics. It also serves as a technological foundation for other ZWSOFT solutions such as ZWSim-EM, ZWSim Structural, and ZWMeshWork.

What particularly distinguishes Overdrive in the field of interoperability is its ability to maintain model integrity during format conversions, significantly reducing geometric problems that typically occur during exchanges between different CAD systems.

Formats and Standards Supported by ZW3D

Broad Compatibility for Maximum Interoperability

ZW3D excels in supporting a wide range of CAD formats, enabling smooth collaboration with partners and suppliers using other systems. This section details the import and export formats supported by ZW3D.

The table below presents the main formats compatible with ZW3D, classified by categories:

| Category | Format | Extensions |

|---|---|---|

| Native Formats | Catia V4 | .model, .exp, .session |

| Catia V5/V6 | .CATPart, .CATProduct, .CATDrawing, .CGR, .3DXML | |

| NX(UG) | .prt | |

| Creo(Pro/E) | .prt, .prt*, .asm, .asm.* | |

| SolidWorks | .sldprt, .sldasm | |

| SolidWorks_2D | .slddrw | |

| SolidEdge | .par, .asm, .psm | |

| Inventor | .ipt, .iam | |

| Neutral Standards | ACIS | .sat, .sab, .asat, .asab |

| STEP | .stp, .step, .stpz | |

| IGES | .ige, .iges | |

| Parasolid | .x_t, .x_b, .xmt_txt, .xmt_bin | |

| JT | .jt | |

| VDA | .vda | |

| 2D Format | DWG | .dwg |

| DXF | .dxf | |

| Mesh and Visualization | STL | .stl |

| OBJ | .obj | |

| 3DXML | .3dxml | |

| XCGM | .xcgm | |

| Others | Image File | .bmp, .gif, .jpg, .jpeg, .tif, .tiff |

| Neutral File | .z3n, .v3n | |

| PartSolutions | .ps2, .ps3 |

This extensive compatibility enables efficient 3D data conversion and facilitates long-term archiving of technical models in standard formats such as STEP or JT.

Interoperability with Other CAD Systems

Versatile Alternative to Established Systems

ZW3D positions itself as an excellent alternative to established CAD solutions such as SolidWorks, Inventor, or Rhino, with similar functionalities but a differentiated approach to interoperability. Its ability to directly open and modify files from other CAD systems without third-party converters represents a major asset for companies working in multi-CAD environments.

ZW3D's interoperability capabilities revolve around three main axes:

- Hybrid volume-surface modeling: Enables precise design simultaneously integrating volumetric and surface approaches, facilitating exchanges with different systems

- Native multi-CAD compatibility: Works directly with SolidWorks, CATIA, NX and other files without intermediate conversions

- CAD-CAM integration: Smooth transfer of design data to manufacturing modules

Interoperability Use Cases

In a typical industrial environment, ZW3D can serve as a central hub for data translation between different CAD systems. For example, a company receiving CATIA models from its clients can open them in ZW3D, modify them if necessary, and then export them to SolidWorks for its manufacturing partners.

This technical data exchange flexibility allows companies to maintain their preferred CAD system while effectively collaborating with partners using other platforms, thus eliminating traditional interoperability barriers.

SimLab: Immersive Experience Solution for ZW3D

Advanced Interactive Visualization

SimLab Composer, distributed by CAD Interop, represents a powerful solution for creating immersive experiences from ZW3D models. This free plugin establishes an intermediate layer between ZW3D and the SimLab Composer application, creating an active link that keeps data synchronized between the two environments.

This integration eliminates the need for repetitive exports and imports: each modification of the model in ZW3D is automatically reflected in SimLab Composer, while preserving the changes made in the visualization environment.

Key Features for Technical Collaboration

SimLab Composer enriches the ZW3D ecosystem with advanced visualization and sharing capabilities:

- Creation of interactive VR experiences in minutes

- Realistic and fast rendering with multiple output formats (images, videos, animations, 360° views)

- Generation of 3D PDF documents integrating interactive 3D views

- Application of materials and texture baking for realistic rendering

- Mechanism simulation from ZW3D models

These features facilitate technical communication between teams and with clients, transforming complex CAD models into understandable visualizations for all project stakeholders, even those without CAD systems.

Best Practices for Exchanging ZW3D Models

Optimizing Interoperability Flows

To maximize the efficiency of data exchanges with ZW3D, certain recommended practices help avoid common data translation problems and ensure model integrity:

- Prefer standard formats such as STEP or JT for exchanges with external partners

- Use the native ZW3D format (.z3) to preserve construction history between collaborators

- Leverage hybrid modeling to facilitate exchanges with systems centered on surfaces or solids

- Systematically verify geometric quality after import/export with integrated healing tools

How to Effectively Manage Multi-CAD Conversions?

For companies working in a multi-CAD environment, adopting a structured data exchange process with ZW3D can significantly improve productivity:

- Define clear exchange standards for each partner CAD system

- Document optimal import/export parameters for each format

- Implement systematic geometric validation after conversion

- Use SimLab to visually validate converted models

- Maintain a library of reference models to test conversions

These practices help establish a robust interoperability workflow around ZW3D, reducing conversion errors and accelerating product development cycles.

Conclusion

CAD data interoperability represents a strategic issue for modern industrial companies, and ZW3D offers a high-performance solution to this problem thanks to its extensive technical data exchange capabilities. With its Overdrive geometric engine, compatibility with a wide range of CAD formats, and hybrid modeling approach, ZW3D enables smooth integration into multi-CAD ecosystems.

The main assets of ZW3D for interoperability can be summarized as follows:

- Native support for numerous standard and proprietary formats

- Advanced modeling capabilities facilitating exchanges between systems

- Integration with SimLab for immersive visualization and sharing

- Flexibility of use as a central data exchange platform

For companies looking to optimize their technical data exchange processes, ZW3D represents a complete solution that can either serve as a main CAD system or as an interoperability hub between different platforms. Its ability to maintain model integrity during conversions makes it a valuable tool for any collaborative multi-CAD design environment.