Generating accurate bills of materials from CAD models represents a daily challenge for engineering professionals. If you still spend hours manually extracting this essential data, you're not alone. A recent study reveals that engineers dedicate up to 30% of their time to documentation tasks, including the laborious creation of Bills of Materials (BOM). Automating this process could radically transform your productivity by reducing this time by 90% while eliminating the risk of costly errors.

Table of contents

- The fundamentals of technical bills of materials

- Challenges and issues in creating CAD BOMs

- Strategic advantages of BOM automation

- Essential features of an extraction solution

- 3DViewStation: optimal solution for your bills of materials

- Practical applications and use cases

- Best practices for effective bills of materials

- Future trends and technological developments

The fundamentals of technical bills of materials

The bill of materials, also called BOM or parts list, constitutes the documentary backbone of any manufactured product. It represents the hierarchical and structured inventory of all components, materials, and subassemblies required for manufacturing a product. Much more than a simple listing, an effective BOM establishes the relationships between different parts, their exact quantities, and the essential characteristics for production.

In today's industrial environment, an accurate bill of materials plays a crucial role at multiple levels:

- Exact identification of each component in a complex assembly

- Optimized planning of procurement and purchasing

- Efficient orchestration of manufacturing processes

- Development of complete and accurate technical documentation

- Rigorous cost assessment and establishment of competitive quotes

Types of bills of materials in industrial environments

The modern industrial ecosystem uses several types of bills of materials, each addressing specific needs in the product lifecycle:

| BOM Type | Main characteristics | Primary use |

|---|---|---|

| Engineering BOM (EBOM) | Organized according to the conceptual structure of the product | Product design and development |

| Manufacturing BOM (MBOM) | Structured according to production sequences | Production planning and assembly |

| Procurement BOM | Focused on supplier references and lead times | Purchasing management and logistics |

| Service BOM | Oriented toward maintenance and repair | After-sales support and customer documentation |

The transition between these different BOMs often represents a critical point in the product development cycle. An EBOM created by engineering must be transformed into an MBOM adapted to production constraints, then into a procurement BOM for purchasing. This sequential transformation constitutes fertile ground for errors and misunderstandings if not properly automated.

Challenges and issues in creating CAD BOMs

Manual generation of bills of materials from CAD models presents numerous challenges that directly impact productivity and documentation quality. These technical obstacles persist in many organizations despite the constant evolution of digital tools.

Common obstacles in manual data extraction

The traditional process of extracting bills of materials faces several major pitfalls:

- Excessive time consumption - Engineers can spend several hours manually compiling information from a complex assembly

- High risk of human error - Omissions, duplications, or data entry errors that can have costly consequences in production

- Difficulty in updating - Each modification to the CAD model requires a complete revision of the bill of materials

- Interoperability problems - Attributes and metadata can be lost during conversions between different CAD systems

- Break in the digital chain - Disconnection between the 3D model and its associated documentation

These challenges are amplified in multi-CAD environments where different native formats and exchange standards coexist. The diversity of systems used by different departments or external partners multiplies the risks of errors and loss of critical information.

Impact of inaccurate BOMs on the product cycle

The imprecision of bills of materials can have cascading repercussions throughout the development and manufacturing cycle:

| Impacted phase | Potential consequences |

|---|---|

| Design | Multiple revisions, delays in concept validation |

| Procurement | Erroneous orders, stock shortages, unnecessary surpluses |

| Production | Line stoppages, costly rework, delivery delays |

| Customer service | Inaccurate documentation, maintenance difficulties |

| Finance | Budget overruns, incorrect cost estimates |

A recent study conducted by Tech-Clarity reveals that BOM errors can account for up to 23% of cost overruns in engineering projects. This reality underscores the strategic importance of a robust solution for automated BOM extraction.

Strategic advantages of BOM automation

Automating the creation of bills of materials fundamentally transforms the documentation approach in engineering. Beyond the obvious time savings, it brings structural benefits that positively impact the entire product development cycle.

Quantifiable benefits of automated extraction

Organizations that have adopted BOM automation solutions report measurable advantages:

- Drastic reduction in generation time - Up to 90% time savings compared to manual methods

- Near-total elimination of errors - 95% reduction in documentation anomalies related to bills of materials

- Guaranteed consistency - Permanent synchronization between CAD model and documentation

- Instant updating - Immediate reflection of design modifications throughout the documentation chain

- Documentation standardization - Harmonization of the format and structure of bills of materials across the company

These productivity gains free up valuable time for engineers, who can refocus on higher value-added tasks such as innovation and design optimization. In the context of global competition, this reallocation of intellectual resources constitutes a considerable strategic advantage.

Improvement in overall documentation quality

BOM automation significantly raises the qualitative level of technical documentation:

| Qualitative aspect | Observed improvement |

|---|---|

| Accuracy | Comprehensive and exact inventory of all components |

| Consistency | Uniformity of information across different documents |

| Information richness | Complete integration of attributes and metadata from the model |

| Traceability | Precise tracking of modifications and versions |

| Accessibility | Structured format facilitating data exploitation |

This qualitative elevation translates into better collaboration between different departments and a significant reduction in interpretation errors. The increased reliability of bills of materials strengthens confidence in technical data and facilitates decision-making at all levels of the organization.

Essential features of an extraction solution

To effectively address the challenges of BOM generation, an extraction solution must integrate a set of key functionalities. These technical capabilities directly determine the added value and return on investment of the tool.

Multi-format compatibility: fundamental requirement

In a heterogeneous industrial environment, the ability to process different CAD formats constitutes an essential prerequisite:

- Major native formats - Direct support for the main CAD systems on the market (CATIA, NX, Creo, Inventor, SolidWorks, etc.)

- Standardized neutral formats - Support for exchange formats such as STEP, JT, 3D PDF

- Visualization formats - Compatibility with lightweight formats (3D XML, STL, etc.)

- Multiple versions - Support for different versions of the same CAD format

- Complex assemblies - Ability to process elaborate hierarchical structures

This versatility ensures the smooth integration of the solution in varied digital ecosystems, without breaking the information chain or requiring potentially damaging prior conversion for data integrity.

Customization and flexibility of extractions

A high-performance solution must offer a high level of adaptability to meet the specific needs of each organization:

- Granular selection of attributes - Ability to precisely choose which metadata to extract

- Display format configuration - Customization of the visual presentation of bills of materials

- Advanced filtering options - Possibility to include/exclude certain components according to defined criteria

- Intelligent grouping - Organization of elements by logical categories (materials, suppliers, etc.)

- Export customization - Adaptation of output formats to the needs of different departments

This flexibility allows the generated bills of materials to perfectly align with the company's specific business processes, thus optimizing their operational utility in each department.

Documentation integration and visualization

The association between bill of materials and visual representation of the model considerably enriches the informational value of the document:

| Functionality | Documentation benefit |

|---|---|

| Interactive model/BOM linking | Bidirectional navigation between parts list and 3D visualization |

| Automatic generation of item numbers | Immediate visual identification of listed components |

| Creation of annotated exploded views | Intuitive understanding of assembly relationships |

| Integrated documentary export | Direct production of complete technical documentation |

| Intelligent annotations | Contextual enrichment of technical information |

This visual dimension transforms the bill of materials from a simple data table into a powerful technical communication tool, facilitating understanding and reducing the risks of erroneous interpretation.

3DViewStation: optimal solution for your bills of materials

Faced with the challenges outlined above, 3DViewStation stands out as a complete and powerful solution for automated extraction of bills of materials from CAD models. Its intuitive approach and advanced features precisely meet the needs of modern industrial organizations.

Universal compatibility with CAD formats

3DViewStation offers exceptional compatibility with the current CAD ecosystem:

- Extended native support - Direct reading of CATIA, NX, Creo, Inventor, SolidWorks formats and other major CAD systems

- Industrial exchange formats - Optimized support for JT, STEP, 3D PDF, 3D XML formats, etc.

- Efficient processing of complex assemblies - Smooth management of elaborate hierarchical structures, even for models with thousands of components

- Complete attribute preservation - Preservation of all technical metadata from the original model, essential for complete bills of materials

This versatility ensures frictionless integration in any multi-CAD environment, eliminating traditional problems of conversion and information loss between heterogeneous systems.

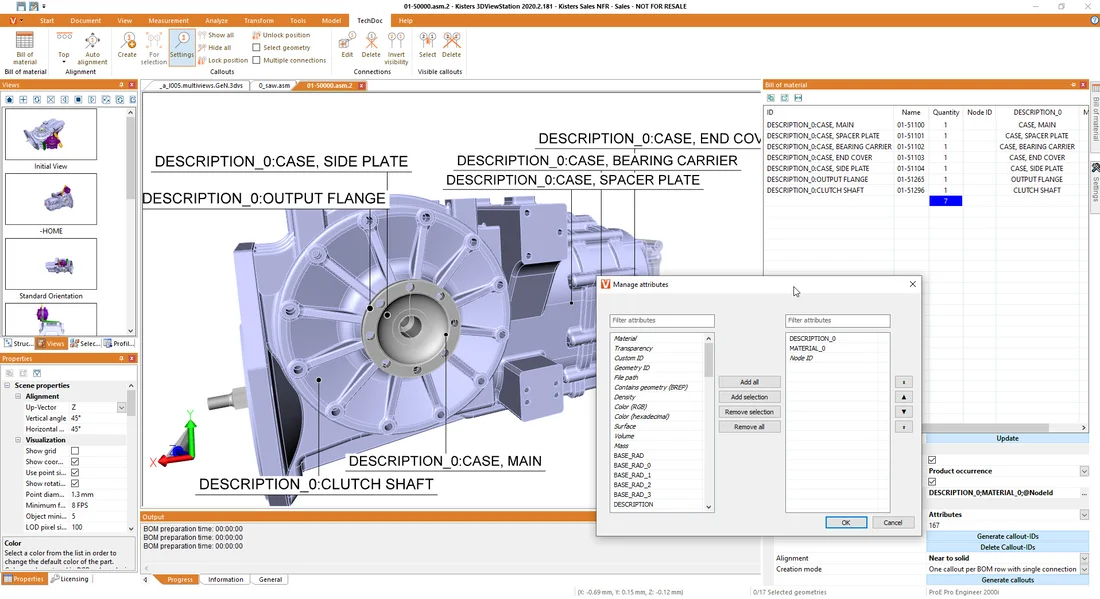

Simplified BOM extraction workflow

One of the major strengths of 3DViewStation lies in its remarkably intuitive extraction process:

- Opening the model - Fast and optimized loading of the CAD file in the interface

- Accessing the dedicated function - Using the specific BOM tool

- Selecting attributes - Precise choice of information to extract according to needs

- Instant generation - Immediate creation of the complete bill of materials

- Visual customization - Format adjustment according to documentation standards

This simplified sequence allows even non-specialist users to quickly generate accurate bills of materials, thus democratizing access to this critical functionality beyond the engineering department alone.

Advanced management of technical attributes

The 2021 version of 3DViewStation has considerably enriched its attribute management capabilities:

| Functionality | Practical application |

|---|---|

| Insertion of custom attributes | Integration of company-specific metadata in the bill of materials |

| Dual use of attributes | Use as textual information or as reference values |

| Complete visual customization | Adaptation of text and connector styles to documentation standards |

| Structured organization | Hierarchization of information according to appropriate business logic |

| Calculated attributes | Creation of derived fields based on existing attributes |

This functional richness allows for the creation of bills of materials perfectly adapted to the specific needs of each department, thus optimizing their operational utility throughout the product lifecycle.

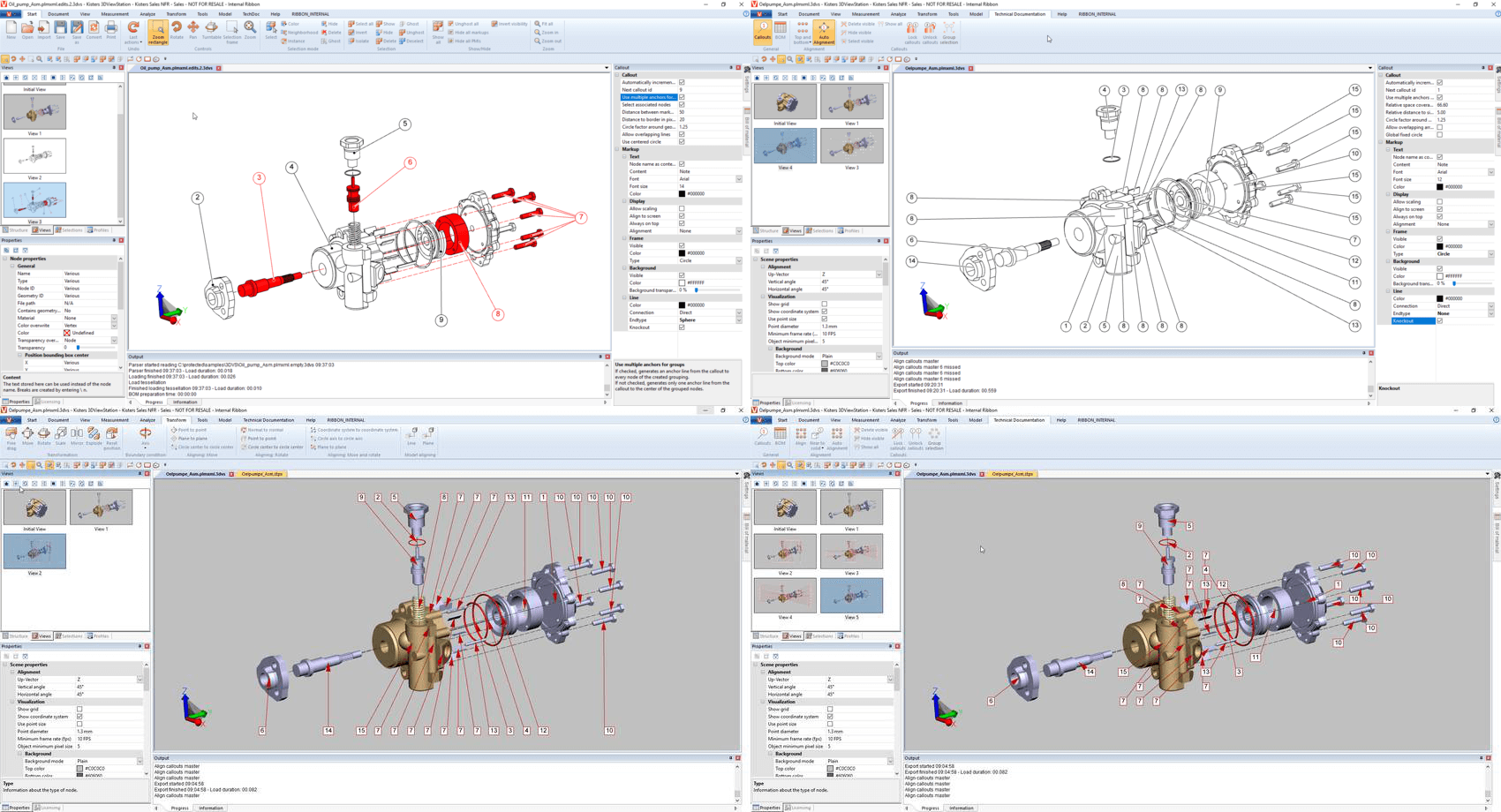

TechDoc Module: enhanced technical documentation

The TechDoc complementary module of 3DViewStation considerably extends the documentary capabilities of the solution:

- Automatic generation of identifiers - Intelligent creation of references for each component

- Flexible reference bubbles - Manual or automatic insertion of visual annotations

- Stylistic customization - Complete adaptation of the appearance of documentary elements

- Smooth BOM/visualization integration - Perfect synchronization between parts list and 3D model

- Advanced documentary production - Creation of complete and professional technical documentation

These features transform simple BOM extraction into a complete documentation creation process, offering an integrated solution for all technical documentation needs.

Export options and system integration

3DViewStation offers multiple options for utilizing the generated bills of materials:

- Direct copy to clipboard - Immediate transfer to other applications

- Export in structured formats - Generation of CSV, Excel or XML files

- Documentation integration - Incorporation into broader technical reports

- Automation API - Integration possibilities with PLM and ERP systems

- Standardized exchange formats - Compatibility with main industrial standards

This flexibility ensures a smooth flow of technical information throughout the company's digital ecosystem, strengthening the continuity of the data chain and facilitating interdepartmental collaboration.

Practical applications and use cases

Bills of materials automatically generated from CAD models have multiple concrete applications in the industrial environment. Their versatility makes them an essential tool at different stages of the product lifecycle.

Comprehensive technical documentation

The automated bill of materials constitutes the central element of numerous technical documents:

- User and maintenance manuals - Precise identification of components for service operations

- Spare parts catalogs - Exact referencing of elements available for replacement

- Assembly instructions - Sequential guide for component assembly

- Compliance documentation - Complete inventory for regulatory certification

- Product technical sheets - Detailed specifications of marketed assemblies

The quality and precision of bills of materials generated with tools like 3DViewStation significantly raise the professional level of this documentation, strengthening the company's brand image with its customers and partners.

Optimization of collaborative processes

Automated bills of materials facilitate collaboration between different stakeholders in the product cycle:

| Collaborative context | Contribution of automated bills of materials |

|---|---|

| Design reviews | Common reference for technical discussions between teams |

| Interdepartmental coordination | Shared language between engineering, production, and procurement |

| Customer-supplier relationships | Unambiguous specifications for orders and deliveries |

| Customer technical support | Precise identification of components during interventions |

| Knowledge transfer | Clear documentation for training and knowledge transfer |

This collaborative dimension proves particularly valuable in organizations where different teams, potentially geographically dispersed, must coordinate their efforts around the same product.

Strategic production planning

Beyond their documentary value, automated bills of materials play a key role in optimizing production processes:

- Organization of assembly sequences - Optimal planning of assembly steps

- Preparation of manufacturing kits - Logical grouping of components for workstations

- Anticipation of resource needs - Precise forecasting of necessary equipment and skills

- Similarity analysis - Identification of standardization opportunities between products

- Variant management - Coherent organization of variations of the same product

These operational applications transform the bill of materials from a simple document into a true strategic management tool for continuous optimization of industrial processes.

Best practices for effective bills of materials

To fully exploit the potential of automated bills of materials, certain optimal practices deserve to be adopted. These recommendations help maximize the value of extracted data and their utility across the organization.

Coherent structuring of source CAD models

The quality of generated bills of materials directly depends on the organization of the original CAD models:

- Logical hierarchy of assemblies - Clear organization of subassemblies according to their function

- Standardized component naming - Coherent system for part identification

- Systematic attribution of metadata - Complete documentation of essential technical properties

- Standardization of references - Use of uniform coding across projects

- Documentation of functional relationships - Clear identification of links between components

This discipline in structuring models constitutes the foundation of effective BOM extraction. Investments made at this level translate into significant gains throughout the documentation cycle.

Strategic customization adapted to departmental needs

The configuration of extractions must adapt to the specific needs of each target audience:

| Department | BOM focus | Priority attributes |

|---|---|---|

| Engineering | Functional structure | Technical specifications, materials, tolerances |

| Production | Assembly sequence | Assembly time, tooling, required skills |

| Procurement | Organization by suppliers | External references, lead times, quantities, costs |

| Customer service | Component accessibility | Lifespan, replacement procedures |

| Quality | Control points | Critical specifications, applicable standards |

This targeted customization transforms the bill of materials from a generic document into a tool perfectly adapted to the specific business processes of each department, thus maximizing its operational value.

Integration into a global documentation process

BOM extraction must be part of a broader documentation strategy:

- Establishment of a validated workflow - Clear definition of the extraction and validation process

- Assignment of responsibilities - Precise identification of roles in BOM management

- Synchronization with information systems - Coherent integration with ERP, PLM and other tools

- Revision management - Structured process for updating and version control

- User training - Skill development for optimal exploitation

This systemic approach ensures that bills of materials do not remain isolated documents but integrate harmoniously into the company's information ecosystem, effectively contributing to overall digital continuity.

Future trends and technological developments

The field of CAD BOM extraction and management continues to evolve rapidly, driven by technological advances and new industrial paradigms. These emerging trends outline the future of this essential discipline.

Intelligent integration into digital ecosystems

The future of bills of materials is moving toward ever-deeper integration:

- Real-time connection with ERP and PLM - Instant bidirectional data synchronization

- Complete digital traceability - Comprehensive tracking of modifications from design to production

- Enhanced interoperability - Smooth exchange of information between heterogeneous systems

- Automation of documentary workflows - Intelligent orchestration of validation processes

- Digital twin powered by BOMs - Integration of bills of materials in complete virtual representations

These developments are leading to the emergence of a unified digital ecosystem where the bill of materials becomes a central element, dynamically connected to all of the company's information systems.

Emerging technologies serving bills of materials

Several technological innovations are currently transforming the approach to bills of materials:

| Technology | Impact on bills of materials |

|---|---|

| Artificial intelligence | Predictive analysis of needs, automatic optimization suggestions |

| Blockchain | Tamper-proof traceability of components and their characteristics |

| Cloud computing | Real-time collaboration on bills of materials, universal accessibility |

| Augmented reality | Superimposition of BOM data on physical objects |

| Big Data | Advanced analysis for assembly and cost optimization |

These converging technologies open new perspectives for transforming bills of materials from simple listings into intelligent tools for decision support and continuous product optimization.

Toward extended mobility and collaboration

The evolution of work modes also influences the approach to bills of materials:

- Universal mobile access - Consultation and manipulation of bills of materials on mobile terminals

- Distributed real-time collaboration - Simultaneous work of geographically dispersed teams

- Contextual sharing - Targeted distribution of relevant information to each stakeholder

- Collaborative annotation - Ability to collectively enrich bills of materials

- Adaptive visualization - Optimized representation according to the context of use

These trends reflect the evolution toward more flexible, collaborative, and connected work environments, where access to precise technical information becomes possible anytime and anywhere.

Conclusion

Automating the creation of bills of materials from CAD models today represents much more than simple documentation optimization: it constitutes a strategic lever for digital transformation for industrial companies.

By eliminating time-consuming and error-prone manual processes, solutions like 3DViewStation free up valuable time for engineers while ensuring optimal precision and consistency of technical data.

This automated approach establishes a dynamic link between 3D design and its documentation, ensuring that each modification is instantly reflected throughout the documentation chain. This perfect coupling between model and bill of materials constitutes the cornerstone of robust digital continuity throughout the entire product lifecycle.

Organizations that adopt these automated extraction technologies equip themselves with a significant competitive advantage: they can respond more quickly to market demands, optimize their production processes, and provide superior quality technical documentation, thus strengthening their positioning in an increasingly demanding industrial environment.