Each year, technical teams spend up to 40% of their time creating documentation. This alarming figure is explained by a process that is often fragmented between design and documentation departments. The good news? Modern technical documentation solutions based on CAD models are radically transforming this reality, enabling considerable productivity gains and smooth technical communication.

The industrial companies that excel today are those that have understood the strategic importance of efficiently reusing their CAD data to create technical documentation that is accurate, accessible, and visually attractive - without requiring specific expertise in 3D design.

Table of Contents

- The Digital Transformation of Technical Documentation

- Critical Applications of CAD Model-Based Technical Documentation

- Essential Features of a High-Performance Solution

- Economic and Operational Impact of Optimized Documentation

- 3DViewStation: Fast and Universal Solution

- Implementation Guide and Best Practices

The Digital Transformation of Technical Documentation

Technical documentation has undergone considerable evolution in recent years, moving from static, isolated documents to dynamic resources directly derived from CAD models. This transformation addresses major challenges for industrial companies:

- Acceleration of product development cycles

- Need to maintain consistency between design and documentation

- Reduction of costs related to document production

- Improvement of the user experience for technicians and customers

Traditional approaches to technical documentation present several significant limitations. They often require manual re-entry of information, generating risks of errors and inconsistencies. The delay between design modifications and their impact on documentation can lead to costly problems in the field. Moreover, these methods compartmentalize technical data, making it difficult to access for non-specialist teams.

The emergence of solutions allowing direct reuse of CAD models marks a decisive turning point. These tools establish a direct link between design data and technical documentation, ensuring up-to-date and accurate information. The advantages of such an approach are multiple:

| Traditional Approach | CAD Model-Based Approach |

|---|---|

| Manual re-entry of information | Direct reuse of design data |

| Time lag between design and documentation | Automatic synchronization of modifications |

| Static and minimally interactive documentation | Dynamic and engaging user experience |

| Limited formats (mainly PDF) | Multiple formats adapted to different needs |

Critical Applications of CAD Model-Based Technical Documentation

The reuse of CAD data for technical documentation finds many essential applications in modern industry. Let's examine the most strategic use cases.

Interactive Spare Parts Catalogs

Spare parts catalogs represent a crucial issue for equipment manufacturers. The traditional approach, based on static illustrations and fixed bills of materials, no longer meets user expectations and generates high production costs.

Technical documentation based on CAD models radically transforms the user experience by enabling:

- Interactive visualization of assemblies, with the ability to zoom, rotate, and explore components

- Precise identification of parts thanks to a ballooning system directly on the 3D model

- Immediate access to technical information (references, dimensions, materials) via associated metadata

- Integration with ordering systems for a seamless experience

For complex assemblies such as industrial machines or vehicles, this approach allows selective display of relevant subassemblies, greatly facilitating navigation and identification of the sought components.

Assembly and Disassembly Instructions

Creating clear and precise assembly instructions represents a considerable challenge for manufacturers. CAD models constitute an invaluable resource for generating visual step-by-step procedures.

The process of creating assembly instructions from CAD models generally includes:

- Loading the complete CAD model of the assembly

- Sequential creation of exploded views for each assembly step

- Addition of annotations, arrows, and contextual textual instructions

- Saving views for each step of the process

- Exporting to the appropriate format (interactive 3D, image sequence, etc.)

This approach presents several decisive advantages:

- Absolute precision of representations, directly derived from design data

- Ability to create animations showing the movement of parts

- Adaptation to different audiences (production, maintenance, end user)

- Easy updating in case of design modification

Documentation for Maintenance and After-Sales Service

Maintenance represents a strategic issue for industrial equipment, with a direct impact on its total cost of ownership. Accurate and accessible technical documentation constitutes a major asset for optimizing these operations.

Documentation based on CAD models allows:

- Immediate access to exploded views and bills of materials for the relevant subassemblies

- Visualization of intervention procedures with animated sequences

- Integration of essential metadata (torque settings, consumable references, etc.)

- Creation of dynamic sections to visualize internal components

For maintenance teams, having interactive technical documentation derived directly from CAD models represents a considerable time saving and significantly reduces the risk of error during interventions.

Essential Features of a High-Performance Solution

To fully exploit the potential of CAD models in creating technical documentation, several key features are essential.

Multi-Format Visualization Without Prior Conversion

In a typical industrial environment, CAD data comes from multiple sources and systems. A high-performance solution must be able to natively process most common CAD formats:

- Proprietary formats of major CAD systems (Catia, NX, Creo, SolidWorks, Inventor, etc.)

- Standardized exchange formats (STEP, IGES, JT, etc.)

- Visualization formats (3D PDF, GLTF, etc.)

This extended compatibility allows easy integration of components from different suppliers or designed on different platforms, without requiring prior conversion that could alter data integrity.

Annotation and Ballooning Tools

The value of technical documentation often lies in its ability to contextualize information. Annotation tools are therefore essential:

- Ballooning system to clearly identify components

- Textual annotations with customizable styles

- Reference lines and directional arrows

- Standardized technical symbols

- Automatic or manual dimensioning

These features allow significant enrichment of 3D models to create clear and precise documentation, adapted to different audiences.

Creation of Exploded Views and Advanced Manipulation

Exploded views constitute a fundamental element of technical documentation. A high-performance solution must offer:

- Assisted or manual creation of exploded views

- Precise control of component positioning

- Saving and management of views for reuse

- Animation of explosion paths to visualize the assembly process

These advanced manipulation capabilities allow the generation of explicit technical illustrations that greatly facilitate the understanding of complex assemblies.

Automatic Generation of Bills of Materials

Bills of Materials (BOM) represent a central element of technical documentation. Their automatic generation from CAD models allows:

- Precise extraction of the product structure as defined in design

- Integration of metadata associated with components (references, materials, etc.)

- Automatic synchronization in case of model modification

- Customization of format and content according to documentation needs

This feature eliminates the risks of error related to manual re-entry and ensures consistency between models and documentation.

Integrated Analysis Tools

Beyond simple visualization, a complete solution must offer analysis tools that enrich technical documentation:

- Creation of dynamic sections to visualize the interior of assemblies

- Precise measurement tools (distances, angles, radii, etc.)

- Thickness analysis with color-coded representation

- Collision detection between components

- Model comparison to identify modifications

These analytical features allow the inclusion of high-value technical information in the documentation, difficult to obtain by other means.

Economic and Operational Impact of Optimized Documentation

The adoption of an approach based on the reuse of CAD models for technical documentation generates substantial benefits, both economic and operational.

Reduction of Time and Costs for Document Production

The most immediate impact concerns the productivity of documentation teams:

- Reduction of 30 to 70% of the time needed to create technical documentation

- Elimination of low-value-added re-entry tasks

- Automation of update processes in case of design modification

- Standardization of documentation processes across the enterprise

This optimization translates into a significant reduction in direct and indirect costs related to document production, while improving responsiveness to product evolutions.

Reduction of Errors and Revisions

The guaranteed consistency between CAD models and technical documentation generates substantial benefits:

- Drastic reduction of documentation errors (incorrect references, imprecise instructions, etc.)

- Reduction of costs related to revisions and corrections

- Prevention of field incidents due to outdated documentation

- Improvement of brand image and customer satisfaction

For industrial companies, these benefits represent not only direct savings but also a significant reduction in operational risks.

Improvement of Internal and External Communication

Technical documentation based on CAD models considerably favors exchanges between different stakeholders:

- Common visual language between design, production, marketing, and customer service

- Accessibility of technical data for non-specialists

- Facilitated multilingual support through the visual approach

- Enhanced customer experience thanks to interactive and precise documentation

This streamlining of communication translates into more effective collaboration and a better understanding of technical issues by all teams.

Optimization of Maintenance and After-Sales Service Processes

The impact of quality technical documentation on maintenance operations is considerable:

- Reduction of 15 to 30% of intervention time thanks to precise instructions

- Reduction of errors during maintenance operations

- Accelerated training of new technicians

- Improvement of equipment availability

These benefits directly translate into a reduction in the total cost of ownership of equipment and an improvement in customer satisfaction.

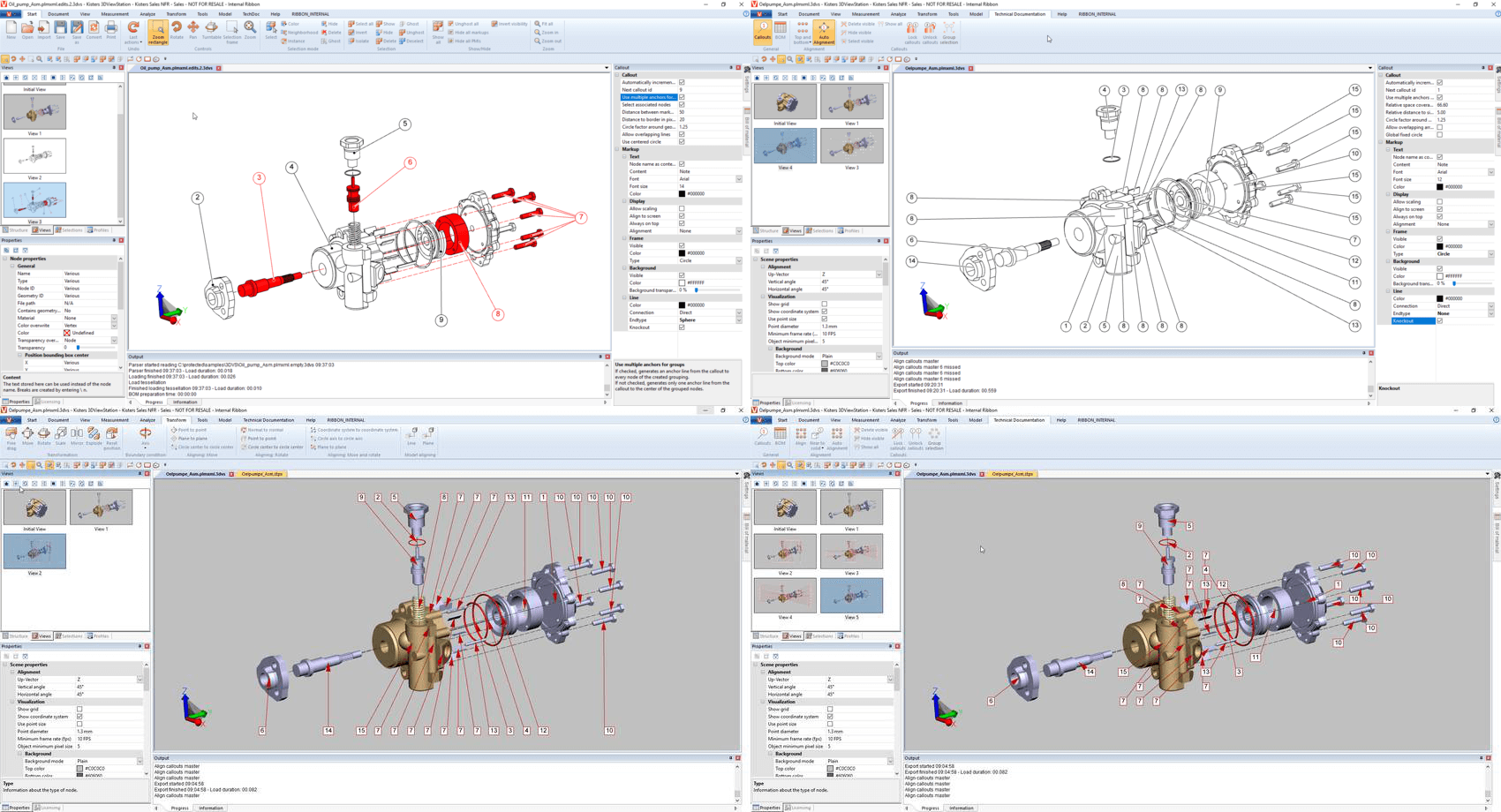

3DViewStation: Fast and Universal Solution

Facing the challenges of CAD model-based technical documentation, 3DViewStation stands out as a particularly high-performance and versatile solution.

General Presentation and Available Versions

Developed by KISTERS, a company with over 50 years of experience and 700 employees spread across 22 offices worldwide, 3DViewStation is a universal CAD visualization software designed to meet the specific needs of technical documentation.

The solution comes in several complementary versions:

- Desktop Version: powerful application for PCs and laptops

- Web Version: cloud solution accessible from a browser

- VR Version: immersive virtual reality experience

- Server Version: automation of conversion and documentation processes

This modularity allows adapting the solution to different usage contexts and easily integrating it into the existing IT ecosystem.

Performance and Key Features for Documentation

3DViewStation is distinguished by exceptional performance, notably:

- Ultra-fast loading of large models (up to 5 GB or 20,000 parts)

- Compatibility with more than 60 CAD formats (Catia, NX, Creo, Inventor, SolidWorks, etc.)

- Direct work on models "as is" without prior preparation

- Intuitive interface accessible to CAD non-specialists

For creating technical documentation, 3DViewStation offers a complete set of features:

| Category | Features |

|---|---|

| Model Manipulation | Creation of exploded views, selective hiding/showing, modifications of colors and transparencies |

| Annotation and Ballooning | Complete ballooning system, texts, dimensions, technical symbols |

| Analysis | Precise measurements, dynamic sections, collision detection, thickness analysis |

| Bill of Materials | Automatic BOM generation, format customization, export |

| Rendering | Multiple modes (shaded, wireframe, technical), advanced graphic effects (silhouette, opaque) |

Integration into the Enterprise Ecosystem

3DViewStation has been designed to integrate harmoniously into the existing infrastructure:

- Complete API allowing task automation (loading, positioning, annotation)

- Integration with PLM, ERP systems and documentation portals

- Connectors available for major platforms (TeamCenter, Windchill, SAP, etc.)

- Export to various formats (images, 3D PDF, vector formats)

This integration capability allows establishing a smooth workflow between design systems and technical documentation tools.

Concrete Applications

3DViewStation effectively responds to the main use cases of technical documentation:

Spare Parts Catalogs

The solution allows creating interactive catalogs with:

- 3D visualization of assemblies with intuitive navigation

- Intelligent component ballooning system

- Integration with ordering systems

- Access to technical metadata (references, dimensions, etc.)

Assembly Instructions

For creating assembly instructions, 3DViewStation offers:

- Step-by-step sequencing of assembly operations

- Automated creation of exploded views

- Contextual annotations for each step

- Export to the appropriate format (interactive 3D, image sequence)

Documentation for Maintenance

In the field of maintenance, the solution offers:

- Management of procedures throughout the product lifecycle

- Bidirectional integration between visualization and technical data

- Immediate access to associated documents (videos, manuals, diagrams)

- Analysis tools for diagnostics and interventions

Implementation Guide and Best Practices

To fully exploit the potential of a solution like 3DViewStation, a methodical implementation approach is recommended.

Key Steps to Deploy a Technical Documentation Solution

The implementation process can be structured in several phases:

- Needs Analysis: precise identification of use cases, CAD formats to support, and documentation requirements

- Technical Evaluation: testing the solution with representative models to validate performance

- Infrastructure Setup: installation and configuration according to the chosen architecture

- Integration with Existing Systems: connection with PLM/PDM, ERP, or other data sources

- Creation of Documentation Templates: development of templates to standardize processes

- Team Training: user support according to their profiles and needs

- Progressive Deployment: production implementation in stages to control change

This sequential approach allows securing implementation and maximizing benefits.

Adoption Strategies to Maximize Benefits

Several key factors contribute to the success of a CAD model-based technical documentation project:

- Early User Involvement: participation of documentation teams from the design phase

- Progressive Approach: starting with high-impact, low-complexity pilot projects

- Process Standardization: definition of common methodologies for document creation

- Resource Centralization: shared library of models, annotations, and templates

- Cross-Functional Communication: raising awareness among all teams about the benefits of the approach

These strategies promote solution adoption and accelerate return on investment.

Training and Supporting Teams

Building team skills constitutes a critical success factor:

- Training adapted to different user profiles (creators vs. consumers)

- Contextualized educational materials with relevant examples

- Personalized support for the first documentation projects

- User community for sharing experiences and best practices

This investment in human capital ensures optimal exploitation of the solution's capabilities.

Performance Measurement and Continuous Improvement

To sustain benefits, regular monitoring of relevant indicators is recommended:

- Documentation production time (before/after)

- Error and revision rates

- Update delay following design modifications

- User satisfaction (creators and consumers)

- Impact on downstream operations (maintenance, customer support)

These measurements allow identifying areas for improvement and continuously adjusting processes.

Conclusion: Towards Integrated and High-Performance Technical Documentation

Technical documentation based on CAD models represents much more than a simple technological evolution – it's a profound transformation of how industrial companies communicate technical information and value their intellectual capital.

By establishing a direct link between design and documentation, this approach eliminates informational silos and ensures perfect consistency throughout the entire product lifecycle. The benefits are multiple and affect the entire organization: cost reduction, quality improvement, process acceleration, and customer experience enhancement.

Solutions like 3DViewStation demonstrate that it is now possible to make this approach accessible to all employees, without requiring specific CAD expertise. Universal visualization, intuitive manipulation, and advanced analysis features transform complex technical data into accessible and usable information.

To remain competitive in an environment where the speed and accuracy of technical information are becoming decisive competitive advantages, industrial companies have every interest in investing in these solutions that democratize access to CAD models and maximize their value throughout the value chain.